The Skills Development Centre undertakes projects that have ability to improve the automotive industry. These might deliver better training outcomes, they may aim to increase the number of people entering the industry, they may work to improve workplaces – increasing apprentice and other employee retention. The SDC may also undertake research to better inform decisions and to produce evidence for submissions to the Government and other stakeholders.

These projects always require the participation of the industry, and we are fortunate that business owners and employees recognise the importance of participating in projects that often require doing things differently and outside of their comfort zone.

Content coming soon.

Content coming soon.

Content coming soon.

Content coming soon.

The Fine Tuning Automotive Mental Health (FTAMH) program will help automotive businesses make their workplace more mentally-healthy.

The Fine Tuning Automotive Mental Health (FTAMH) program will help automotive businesses make their workplace more mentally-healthy.

Funded by WorkSafe’s WorkWell Mental Health Improvement Fund and developed with the help of Alcohol and Drug Awareness Australia, FTAMH aims to provide information, resources and practical measures to identify and prevent mental health issues in the workplace.

By participating in the program, employers will gain an understanding of different work-related risk factors associated with mental health in the work environment, including:

By participating in the program, employers will gain an understanding of different work-related risk factors associated with mental health in the work environment, including:

- unreasonable behaviours, such as bullying and sexual harassment

- poor workplace relationships

- conflict and disputes in the workplace

- poor role clarity and recognition

- inadequate support and poor training for job roles

- unhealthy physical work environments

- workload stress.

Activities within this program focus on these risk factors, with information on how they impact on the workplace and guidance on how they can be managed. Employers will be assisted by program facilitators to assess workplace practices and to implement a mental health action plan tailored to their identified needs.

Activities within this program focus on these risk factors, with information on how they impact on the workplace and guidance on how they can be managed. Employers will be assisted by program facilitators to assess workplace practices and to implement a mental health action plan tailored to their identified needs.

Automotive businesses can participate in the program and receive their free resource pack by visiting the Fine Tuning website.

For more information, please contact the Fine Tuning Team on 03 9829 1130 or via email.

Communication is key

More than 50 percent of automotive apprentices don’t finish

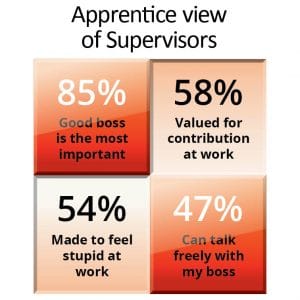

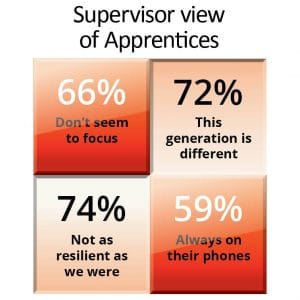

Research has found communication breakdown as the number one reason for apprentice drop-outs. It’s not necessarily about having the most modern workshop or the best wages. Research also found that those supervisors who saw this generation of apprentices as the same as any other generation had fewer issues with drop-outs.

The Australian Chamber of Commerce and Industry commissioned VACC to undertake research into improving apprentice retention in the automotive industry. This research has identified six problem areas in apprentice-supervisor communication.

VACC created 10 short videos to help supervisors and apprentices improve communication and address these problem areas. Supervisors and apprentices report these strategies have made a significant improvement in communication.

These videos include communication problem scenarios and case studies of small and large automotive businesses who have good relations between apprentices and bosses.

Research Project | Key Findings | Strategies | Report

Misunderstanding

Prevent accidents and misunderstanding by explaining ground rules and the way you do things in your workshop to your new apprentice.

Prevent accidents and misunderstanding by explaining ground rules and the way you do things in your workshop to your new apprentice.

Mistakes

Mistakes are a normal part of learning in an apprenticeship. Supervisors have several options for resolving issues, depending on the outcome of the mistake and frequency.

Mistakes are a normal part of learning in an apprenticeship. Supervisors have several options for resolving issues, depending on the outcome of the mistake and frequency.

Punctuality

Sometimes being late is unavoidable, but everyone is in a team. Customers expect their vehicles to be ready on time, and bosses need to know where workers are.

Sometimes being late is unavoidable, but everyone is in a team. Customers expect their vehicles to be ready on time, and bosses need to know where workers are.

Understanding

Mutual understanding and respect is key to positive apprentice-supervisor relations and essential for the apprentice to become a part of the business.

Mutual understanding and respect is key to positive apprentice-supervisor relations and essential for the apprentice to become a part of the business.

Phones

Smart phones have completely changed the way we live and communicate, particularly among young people. Address the issue of phones in the workplace.

Smart phones have completely changed the way we live and communicate, particularly among young people. Address the issue of phones in the workplace.

Explaining

There are many time pressures in the workplace, but extra time spent explaining a task can mean less time spent fixing it if it is done incorrectly.

There are many time pressures in the workplace, but extra time spent explaining a task can mean less time spent fixing it if it is done incorrectly.

Improve communication in your workplace

Supervisors and apprentices feel more comfortable and are more productive with better communication in the workplace. Taking on an apprentice is no small commitment, and losing an apprentice is difficult for everyone involved. Good communication means issues can be raised and addressed before they become a significant problem.

Employers, supervisors, apprentices and trainers in the industry identified six main areas of communication breakdown between supervisors and apprentices in the workshop.

The videos demonstrate a positive solution in each situation. Each video is linked to a page with suggestions on how to use it in your workplace and a poster that can be printed off and filled out at a toolbox meeting.

CASE STUDIES

Two large and two small automotive businesses demonstrate the benefits of a positive workplace culture and strong communication between all staff, including apprentices. Each gives an insight into how they have addressed the six identified problem areas.

Hallam Truck Centre

Hallam Truck Centre’s apprenticeship program focuses on developing a culture based on strong communication and understanding between the supervisor and the apprentice. This has resulted in improved apprentice retention rates since the program’s inception.

William Adams

William Adams focuses on two-way communication not only between apprentices and supervisors, but also between apprentices and upper levels of management. Developing these strong working relationships helps apprentices feel that they are an integral part of the business.

Turbo Engineering

Turbo Engineering promotes a collaborative learning culture in its workplace and employs a flexible phone policy that understands the positive role that phone technology can have towards learning. Apprentices also play a role in the company’s customer service. Supervisors ensure apprentices keep learning new skills at work.

Rob’s Auto Elec’s

Rob’s Auto Elec’s fosters a workplace culture that focuses on apprenticeships as a learning process. The company’s approach to teaching is to provide a learning process that adapts to the apprentice’s learning style, whether it’s academic or hands-on. Supervisors focus on setting a standard for apprentices to follow.

Feedback from industry Apprentices, supervisors and trainers who took part in this project have responded positively. Surveys found communications in the six identified problem areas improved by seven to 13 per cent. Find out more.

Apprentices and supervisors shared their thoughts:

- “I will be showing all our employees the videos. All the messages have value for all employees.”

- “Sometimes the qualified guys can forget how the obvious for them is not so obvious for the new apprentice.”

- “I will include the video in the induction package for new apprentices.”

- “I know if I have an appointment in work hours to give plenty of notice so the managers know that I will be absent for the given times.”

If you wish to make a comment about the Apprentice Communication and Retention Project, please send us an email.

The Productivity Leadership Program has been established by Australian Chamber of Commerce and Industry (ACCI) with the assistance of funding provided by the Department of Employment.